TABLE OF CONTENTS

|

Introduction

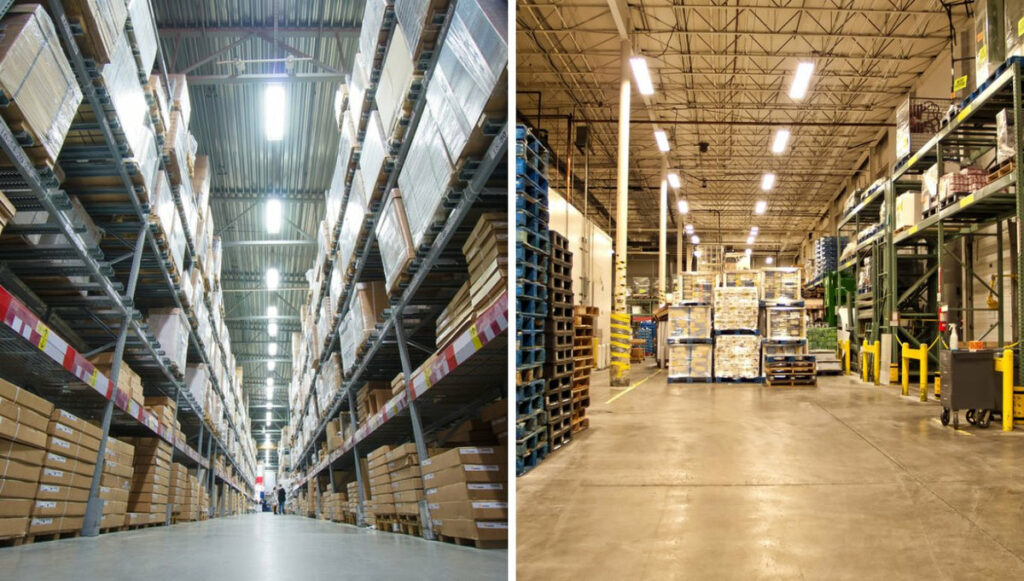

Within the bustling world of warehouses and distribution facilities, the importance of correct lighting can’t be overstated. Past mere illumination, strategically deliberate lighting techniques contribute to productiveness, security, and general operational effectivity. This text delves into the important lighting necessities for warehouses, exploring varied elements, applied sciences, and design concerns to make sure optimum lighting options.

Sorts of Warehouse Lighting

Basic Illumination

Basic illumination serves as the first supply of sunshine, illuminating all the warehouse area uniformly. It facilitates fundamental duties resembling navigating aisles, finding stock, and conducting routine operations.

Process Lighting

Process lighting targets particular work areas throughout the warehouse, offering centered illumination for detailed duties resembling packaging, sorting, and high quality management. Such a lighting enhances visibility and reduces eye pressure amongst staff.

Emergency Lighting

Emergency lighting is essential for sustaining visibility throughout energy outages or different emergency conditions. It contains backup lighting techniques and exit indicators to information occupants safely out of the ability.

Components Influencing Warehouse Lighting

Warehouse lighting necessities are influenced by varied elements, together with:

-

Warehouse Format and Design: The scale, form, and structure of the warehouse dictate the position and configuration of lights to make sure ample protection.

-

Nature of Operations: Totally different warehouse actions, resembling storage, choosing, and loading, might require various ranges of illumination tailor-made to particular duties.

-

Security Rules: Compliance with security requirements and rules mandates correct lighting ranges to reduce accidents and guarantee a safe working surroundings.

Key Issues for Warehouse Lighting

Power Effectivity

Choosing energy-efficient lighting options not solely reduces operational prices but in addition aligns with sustainability targets. LED lighting, specifically, gives important power financial savings and longevity in comparison with conventional lighting applied sciences.

Upkeep Necessities

Selecting lights which might be simple to take care of and restore is crucial for minimizing downtime and guaranteeing steady operation. Accessible fixtures and long-lasting parts contribute to decrease upkeep prices in the long term.

Mild Distribution and Uniformity

Attaining uniform mild distribution throughout the warehouse flooring minimizes shadows and glare, creating a snug and visually constant surroundings for staff. Correctly designed lighting layouts account for top variations and obstructions to take care of constant brightness ranges.

Standard Lighting Applied sciences

LED Lighting

LED (Mild Emitting Diode) lighting has revolutionized the warehouse lighting panorama with its power effectivity, lengthy lifespan, and superior efficiency. LED fixtures present vibrant, uniform illumination whereas consuming considerably much less power than conventional lighting sources.

Excessive-Depth Discharge (HID) Lighting

HID lighting, together with steel halide and high-pressure sodium lamps, has been a staple in warehouse lighting for many years. Though much less energy-efficient than LEDs, HID fixtures provide excessive lumen output and are appropriate for large-scale purposes.

Fluorescent Lighting

Fluorescent lighting stays a cheap choice for warehouses, providing reasonable power financial savings and widespread availability. Whereas not as environment friendly as LEDs, fluorescent fixtures are nonetheless utilized in areas the place upfront prices are a major concern.

Lighting Design Suggestions

Correct Placement of Fixtures

Strategic placement of lights ensures uniform illumination all through the warehouse whereas minimizing glare and shadows. Mounting fixtures at optimum heights and angles maximizes mild distribution and enhances visibility.

Use of Movement Sensors

Incorporating movement sensors into lighting techniques helps preserve power by mechanically adjusting illumination ranges based mostly on occupancy. Dimming or turning off lights in unoccupied areas reduces power consumption with out compromising security or performance.

Incorporating Pure Mild

The place possible, leveraging pure mild by means of skylights, home windows, or translucent roofing panels dietary supplements synthetic lighting, decreasing reliance on electrical fixtures throughout sunlight hours. Pure mild additionally enhances worker morale and well-being by offering a connection to the outside.

Advantages of Optimum Warehouse Lighting

Enhanced Productiveness

Effectively-lit work environments promote productiveness by decreasing errors, rising accuracy, and fostering a way of alertness amongst staff. Sufficient lighting additionally facilitates environment friendly job completion, resulting in greater throughput and operational effectivity.

Improved Security

Correctly illuminated warehouses reduce the danger of accidents and accidents by enhancing visibility and decreasing tripping hazards. Clear visibility of signage, tools, and emergency exits ensures fast response in emergency conditions, mitigating potential dangers.

Price Financial savings

Investing in energy-efficient lighting options interprets into long-term price financial savings by means of decreased electrical energy consumption and decrease upkeep bills. The longevity of LED fixtures minimizes alternative and upkeep prices, additional bolstering the monetary advantages.

Widespread Challenges and Options

Glare and Reflections

Glare and reflections from lights could cause discomfort and visible impairment for staff. Using diffusers, baffles, or directional lighting helps reduce glare whereas optimizing mild distribution for task-specific areas.

Temperature Management

Conventional lighting sources resembling HID lamps generate important warmth, contributing to thermal discomfort and elevated cooling prices. LED lighting produces minimal warmth output, decreasing the pressure on HVAC techniques and sustaining comfy working situations.

Upgrading Current Lighting Methods

Retrofitting outdated lighting techniques with energy-efficient LED fixtures gives a cheap resolution to enhance illumination high quality and scale back power consumption. Authorities incentives and rebates may additionally be obtainable to offset the upfront prices of upgrades.

Case Research

Profitable Implementation of Warehouse Lighting Options

A number of firms have realized tangible advantages from upgrading their warehouse lighting techniques. Case research showcasing improved productiveness, power financial savings, and worker satisfaction exhibit the transformative influence of strategic lighting investments.

Future Tendencies in Warehouse Lighting

Sensible Lighting Methods

The mixing of sensible lighting techniques with superior sensors and controls allows dynamic adjustment of illumination ranges based mostly on occupancy, daylight ranges, and operational necessities. Sensible lighting options provide enhanced flexibility, power financial savings, and data-driven insights into warehouse operations.

Integration with IoT Expertise

The convergence of lighting techniques with Web of Issues (IoT) expertise allows real-time monitoring, predictive upkeep, and seamless integration with different sensible gadgets. IoT-enabled lighting platforms empower warehouse managers with actionable insights to optimize power utilization and improve operational effectivity.

Conclusion

In conclusion, lighting necessities for warehouses embody a mess of things starting from power effectivity and upkeep to security and productiveness. By embracing revolutionary lighting applied sciences, adopting strategic design rules, and prioritizing worker well-being, warehouses can obtain optimum lighting options that drive effectivity, security, and price financial savings.

FAQs

-

How does warehouse lighting influence productiveness?

Warehouse lighting straight influences productiveness by bettering visibility, decreasing errors, and enhancing worker morale and well-being. -

What are the protection implications of insufficient lighting in warehouses?

Insufficient lighting will increase the danger of accidents, accidents, and office incidents attributable to decreased visibility and compromised security measures. -

How can energy-efficient lighting options profit warehouse operations?

Power-efficient lighting options provide price financial savings, decreased environmental influence, and enhanced operational effectivity by means of decrease electrical energy consumption and upkeep necessities. -

What function does lighting design play in optimizing warehouse environments?

Lighting design influences visibility, consolation, and security inside warehouse services, guaranteeing correct illumination of labor areas whereas minimizing glare and shadows. -

Are there any authorities rules concerning warehouse lighting requirements?

Sure, authorities rules set up minimal lighting necessities for workplaces, together with warehouses, to make sure ample illumination ranges for security and productiveness.

Source link